Wire Displacement Sensor / SM40-WY Wire Displacement Sensor

Product Categories Wire Displacement Sensor

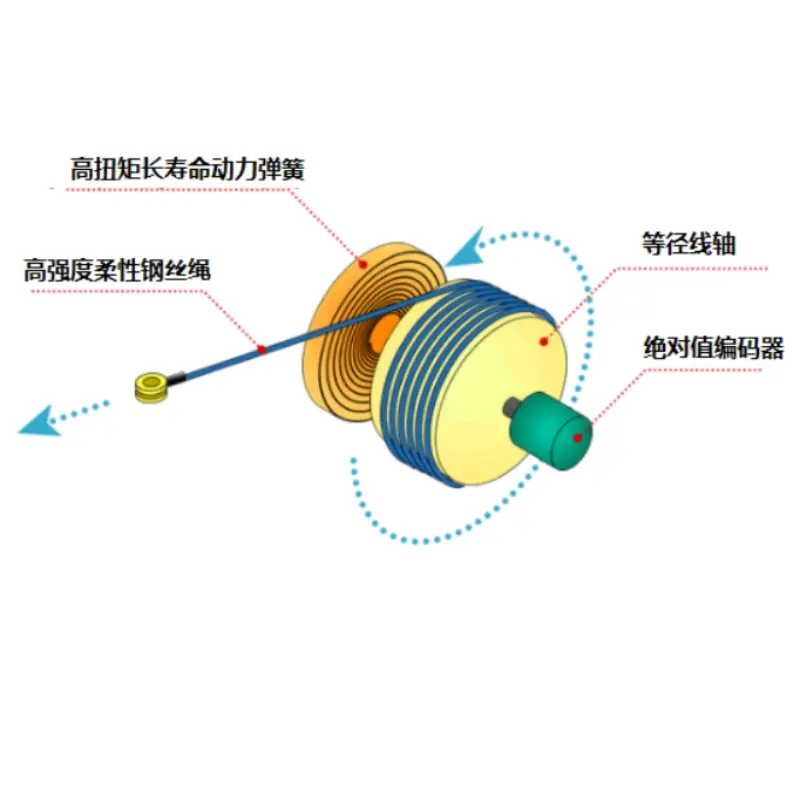

The wire-drawn displacement sensor is composed of a photoelectric acquisition part and a set of mechanical shell devices. The shell is made of aluminum alloy material, and the outer surface is oxidized, which is hard and wear-resistant; it can resist pressure and shock, and adapt to high temperature, high pressure, and other harsh use occasions; the winding wire is an original imported stainless steel wire rope, the outer layer of which is plastic-coated, with strong corrosion resistance, high strength, and no telescoping; the winding spring mechanism is made of imported stainless steel materials, which is corrosion-resistant and stable. It makes it an industrial control preferred displacement sensor with compact structure, small installation space size, long measurement stroke, convenience and flexibility, and high-precision measurement. This is a large-scale wire (rope) displacement sensor, used to measure linear distances of 0-20000mm in length. The product adopts a standardized CAN bus communication interface, which can be sturdy and durable, especially suitable for short distances and high-resolution occasions.

Application

The wire-pull displacement sensor is composed of a photoelectric collection part and a set of mechanical shell devices. The shell is made of aluminum alloy material, and the outer surface is oxidized, which is hard and wear-resistant; it can resist pressure and shock, and adapt to various harsh use occasions such as high temperature and high pressure; the reel is an original imported stainless steel wire rope, which is coated with plastic on the outer layer, has strong corrosion resistance, high strength, and no telescoping; the winding spring mechanism is made of imported stainless steel material, which is corrosion-resistant and stable in reeling. It makes it an industrial control preferred displacement sensor with compact structure, small installation space size, long measurement stroke, convenience and flexibility, and high-precision measurement.

This is a large-scale pull-wire (rope) displacement sensor, used to measure the linear distance of 0-20000mm. The product adopts the standardized CAN bus communication interface, which is durable and especially suitable for short distance and high resolution occasions.

Features

This product is easy to install and has a spare installation reference surface with multiple options according to needs; small installation space and low installation difficulty; no guide is required, and mechanical tolerance does not affect the measurement accuracy; it is widely used in linear guide systems, hydraulic cylinder systems, telescopic systems, storage position positioning, pressure machinery, papermaking machinery, textile machinery, metal sheet machinery, packaging machinery, printing machinery, level controllers, construction machinery and other related dimensional measurement and position control; it can be connected to PLC or secondary instruments, single-chip microcomputers and other acquisition systems.

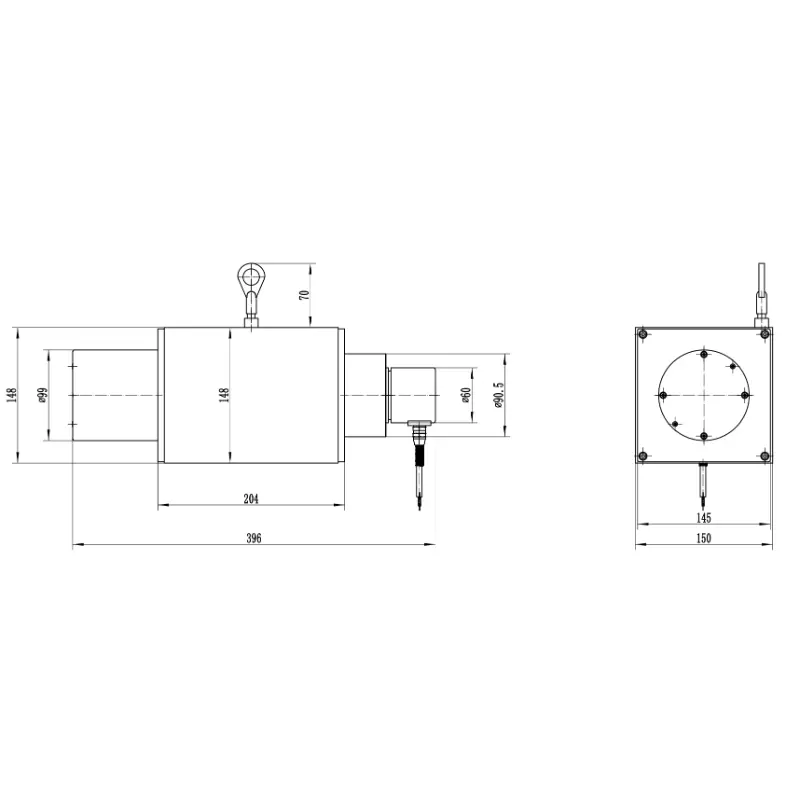

Mechanical indicators

1. Measuring stroke: 0~20000mm

2. Measuring wheel circumference: 333mm

3. Resolution: ≥0.04mm

4. Repeatability: ≤0.1%

5. Rope pulling speed: maximum 3m/s

6. Exit tension: 15 N ~ 20 N

7. Wire rope: Highly flexible multi-strand 316 plastic-coated stainless steel rope, elastic reel

8. With guide mechanism, the angle of the pull rope can be changed;

9. The dust and grease on the pull rope can be self-cleaned without interference;

10. Wire rope diameter: 0.8mm

11. Shell material: Aluminum alloy precision mold, surface anti-static interference

12. Protection grade: IP54

13. Weight (excluding encoder): ≈5 kg (20 meters)

14. Service life: 1 million times

15. Shock: ≤ 100g, 3ms

16. Vibration: ≤ 10g (10Hz-2000Hz)

Technical indicators

1. Ambient temperature: -20℃~+60℃;

2. Relative humidity: ≤95% (non-condensing);

3. Working voltage: 10~24V (DC);

4. No-load current: ≤90 mA;

5. Working current: ≤800mA;

6. Meet the explosion-proof mark: Exd I Mb;

7. Communication interface: Can

8. Four-core mining cable, coal safety demonstration;

9. Emission interference complies with EN61000-6-4

10. Anti-interference complies with EN61000-6-2

11. CANopen encoder complies with DS301 V4.02 standard